Hybrid Components

- Kolektor >

- Kolektor Mobility >

- Hybrid Components

Connection for reliable mobility

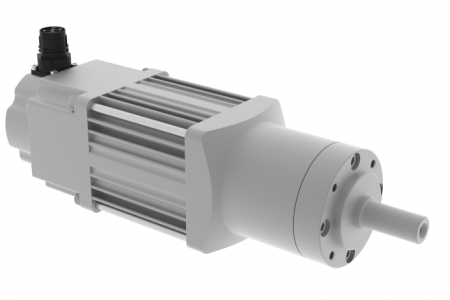

Our mission is to offer hybrid components that are made from injection molded polymers combined with precision metal parts and/or functional components. Such products serve as electrical power and/or signal connectors or heating elements within housing for electrical devices (drives, actuators, pumps, sensors, control units and other mechatronic products) in automotive industry.

From A samples to industrialization with state-of-the-art technologies is the way we address the needs of our customers.

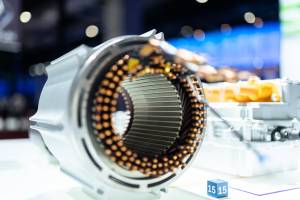

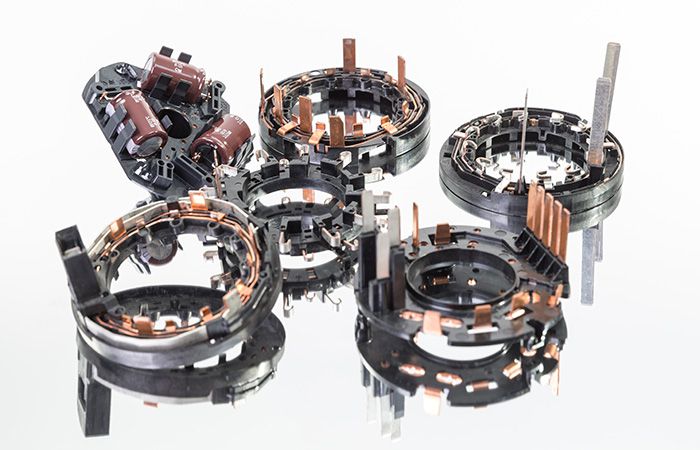

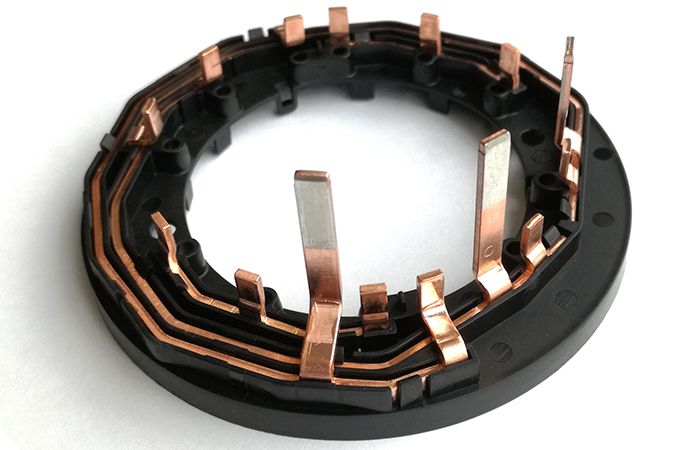

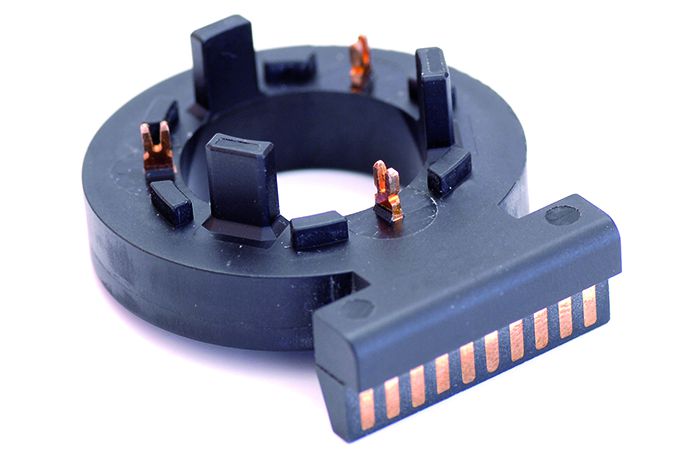

Electrical motor connectors for electrical drives & alternators

- power connection of BLDC (EC) stators

- slip rings

Sensor integration

-

custom sensor integration with or without functional components

Interconnection assemblies for mechatronics

- actuator

- pumps

- ECU power and signal connection housings with or without functional component

Precision polymer parts

- precision polymers

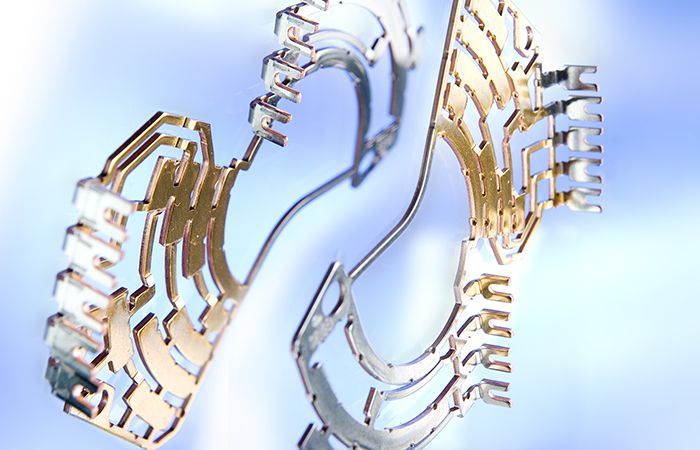

Precision stamping parts for hybrid components, connectors

- aluminum, steel or stainless steel with 0.08–2.0 mm material thickness

- EloPin and Press-fit stamping parts

Heating subassemblies

- heating elements

Interior and exterior assemblies for visual parts

- custom assemblies

- interior and exterior parts

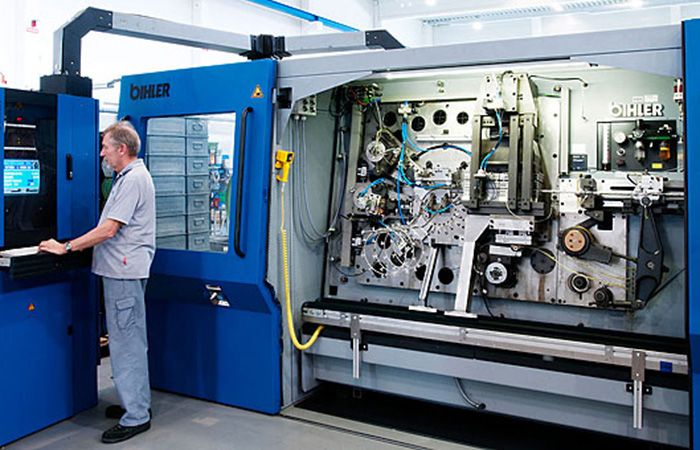

An attractive technology basket

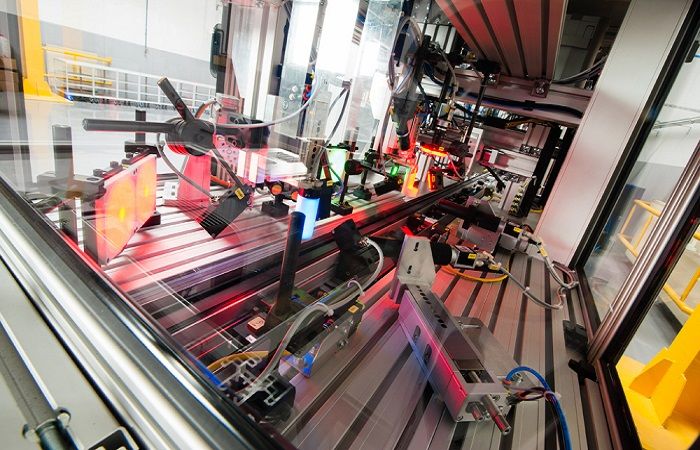

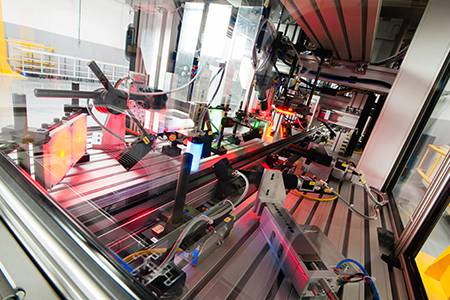

Stamping

- reel-to-reel

- press-fit

- IDC-Insulation displacement connector

Plating

- reel-to-reel

- barrel

Polymer processing

- thermoset (EP, PF, BMC)

- injection molding

- transfer molding

- thermoplastic

- insert molding (metal, magnet, electronic parts)

- 2K

- GIT

Connection

- laser welding

- hot staking

- resistance welding

- ultrasonic welding

- wire bonding

- soldering

- gluing

Sealing

- thermoset

- potting

- 2K

- vacuum impregnation

Why work with us

Competences

- from A samples to technology concept proposal (mechanical construction, simulation, prototyping)

- from validated technology solution to industrialization

- injection & compression molding experience (different thermoplastic & thermoset materials)

- re-forming and surface treatment of non-ferrous metal

- design optimization (FEM, FLOW and THERMAL analysis)

- production process optimization

- optimal material selections

Advantages

- excellent engineering expertise and experienced professional team

- excellent project management according to TS 16949 and ISO 14001

- certified management systems

- efficient and flexible logistic processes

- in-house manufacture of tools & production equipment

- optical & electrical inspection

Contact us

Together we can find the right solution