Less environmental impact

09. 12. 2019 Elektronika in pogoni

When setting strategies for the future, Kolektor co-creates megatrends. One of the global trends in industry in general is focusing on reducing the environmental impact. In the Mobility Components and Systems strategic business unit, we strive to make our products with as low burden on the environment as possible. We use appropriate clean technologies and develop solutions with the lowest carbon footprint. We are present mostly in the field of automotive technology where our product portfolio must be adapted to the global changes, which means that it must be suitable for the “cleanest” possible vehicles.

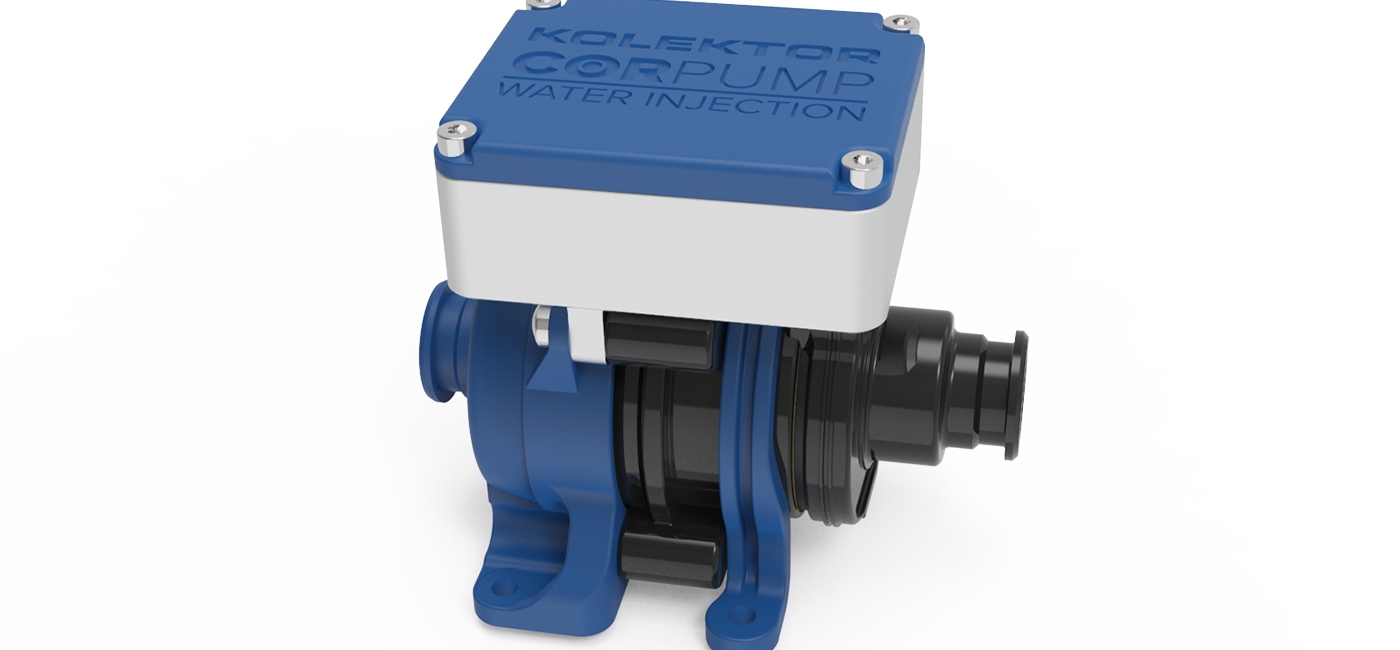

COR pump

More powertrain efficiency

The automotive industry trends are focused on increasing vehicle efficiency, developing autonomous vehicles and reducing harmful emissions. Road traffic is only one of the contributing factors to the greenhouse effect (together with air transport, it can be attributed to almost 25 percent of greenhouse gas emissions). The most harmful to our health are particulate matter and nitrogen oxide (NOx) emissions. Current legislative changes impose increasingly stringent restrictions on tailpipe emissions and fuel consumption for internal combustion engines (ICEs). This trend encourages engine manufacturers to seek new solutions to achieve lower levels of pollution without reducing the engine capacity and the market attractiveness of the vehicle.

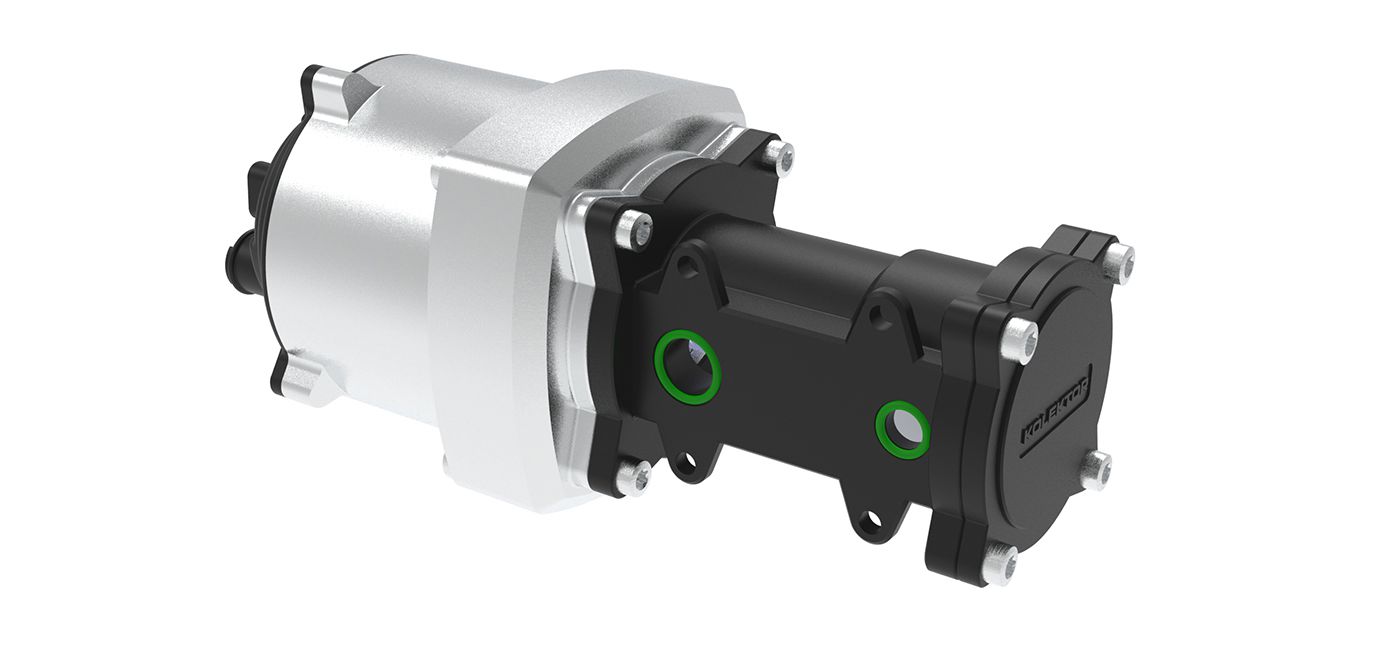

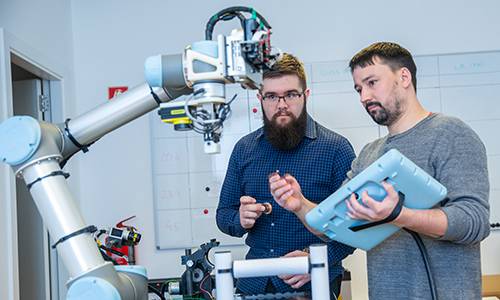

Improving powertrains is one way to make cars more efficient. One of such systems is a water injection system where water is injected into the engine compartment to cool the engine and thus increase the density of the fuel and air mixture.

COR water injection pump for ICE systems

With the water pump, emissions can be reduced and the efficiency of internal combustion engines can be increased. One such product is a pump with COR pump technology to increase the pressure to compress a liquid (water, methanol mixture) before injection into a combustion chamber. This results in lower engine temperature, lower exhaust gas temperature, reduced engine clatter, improved combustion phases, and reduced NOx and CO2 emissions.

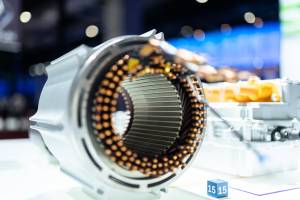

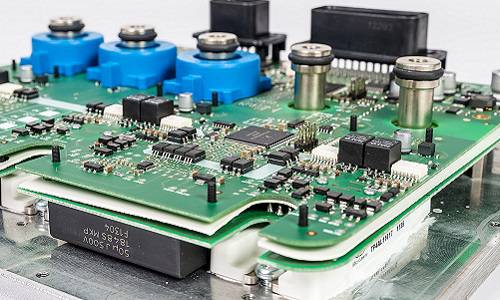

COR pump technology

COR pumps combine the advantages of gerotor and axial piston pumps. They are classified as volumetric pumps and divided into two subgroups: DoppelRotor (COR-DRP) and multi-chamber Tumbling (COR-TMC). What is special about these pumps is the patented three-dimensional gear design.

Depending on the type of pump (pressure pump, compressor, vacuum pump), different product designs and forms are possible. The main components of the pump (made by injection molding of a dimensionally stable polymeric material with high mechanical and thermal performance) allow for a highly competitive quality-price ratio. The COR pump system includes 3D software that allows the user to study fluid behavior in three dimensions and optimize conditions according to the specifications given.

Do not overlook

Sources

- http://sptm.si/wp-content/uploads/2019/05/ETM_publikacija_2016.pdf (25. 11. 2019)

- https://ec.europa.eu/eurostat/statistics-explained/pdfscache/1180.pdf (25. 11. 2019)

- Munih, J. (2017). Ovrednotenje procesa utekanja zobniške črpalke. Magistrsko delo, Ljubljana: Univerza v Ljubljani, Fakulteta za strojništvo.

- Petrič, K., Munih. J (2019). Application of COR pump technology in positive displacement machines. TMC 2019.