Efficient Cooling & Heating, Maximum Performance!

03. 03. 2025 Mobility, Magnetika, Hibridika

Modern cars, especially EVs, use advanced thermal management systems with liquid cooling, heat pumps, and smart sensors to optimize energy use and extend component lifespan.

To achieve efficient cooling and heating—and with it, maximum vehicle performance—every small part matters. That’s why we deliver components that help you reach peak efficiency.

Thermal management in cars

Thermal management regulates the temperature of various vehicle components to ensure optimal performance, efficiency, and safety. It involves cooling, heating, and maintaining the correct temperature for several critical systems:

- Engine Cooling: Prevents the engine from overheating by circulating coolant through the radiator and engine block.

- Battery Thermal Management for EVs & Hybrids: Keeps battery temperature within an optimal range to prevent degradation and maximize performance.

- Cabin Climate Control: Manages heating, ventilation, and air conditioning (HVAC) for passenger comfort.

- Power Electronics Cooling: Protects components like the inverter, motor controller, and chargers from overheating.

- Transmission Cooling: Ensures smooth operation and longevity of the transmission system.

- Waste Heat Recovery: uses excess heat (from the engine or batteries) to improve overall efficiency.

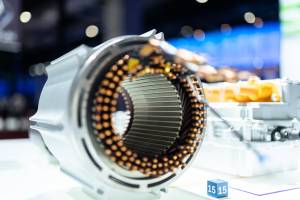

State of the art components for thermal management solutions

As a global provider of mobility components and systems, with more than 60 years of experience, our research and development team is actively tackling the challenges of thermal management for EVs and hybrid cars, especially components for electric water pumps, coolant valves, expansion valves and other solutions, including:

- Rotors

- Covers with connectors

- Housings

- IDC solutions

Components that help you achieve maximum performance

To achieve efficient cooling and heating-and with it, maximum vehicle performance-even the smallest part counts! This is where our expertise as a component developer and manufactirer comes into play.

Here are jus a few of our key strenghts:

- Production of over 15 million water pump rotors per year, including complex gear shapes.

- Development and compounding of high-filled neodymium/ferrite bonded materials (offering SMFeN material for stable pricing).

- Specialists in precision overmolding (R2R and 2K injection molding).

- In-line magnetization and measuring equipment.

- In-house production of terminals.

- Own development of IDC solutions.

- Production at seven locations in the EU and one in Asia, utilizing standardized production lines to minimize customer investment.

- Additional capabilities: plating, precision stamping, welding, bonding, and more.

Join us at Coiltech 2025 in Augsburg!

We are excited to showcase our thermal management solutions at Coiltech Deutschland 2025. Visit us from March 26. - 27, 2025, at the Messe Augsburg, and discover why leading automotive industry players trust us.

Visit us in Hall 2 / Booth E06 (free admission)