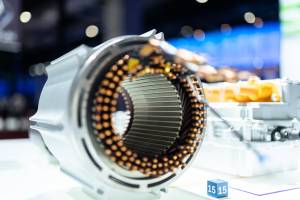

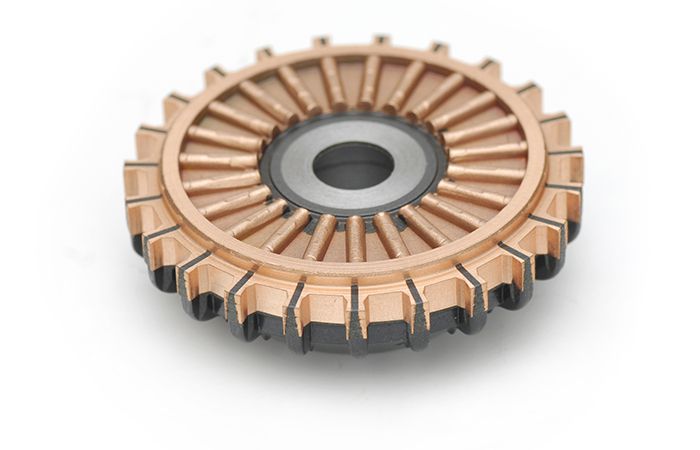

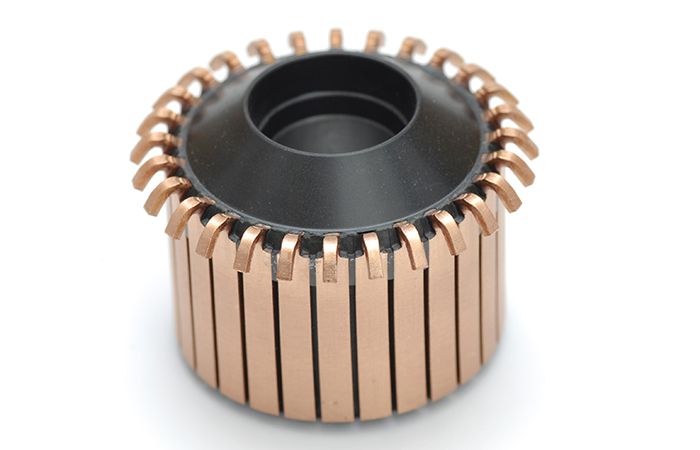

Commutators

- Kolektor >

- Kolektor Mobility >

- Commutators

We have produced over 10 billion commutators so far

Commutators drive our everyday life. Each time you push a button in a car to set a seat or open a window, commutators that are an integral part of every electric motor, enable this.

Do you have a mid-range car? Dozens of commutators provide you with comfort. The same applies to your home, where small kitchen appliances buzz in the kitchen and washing machine hums in the bathroom.

Our main objective is to meet and exceed customers' expectations by constantly improving our products and services. We achieve this with

- ensuring long life of the commutation system in aggressive fuels

- ensuring the expected life of the high-end household appliances and professional power tools

- ensuring high number of restart cycles in start-stop systems

- reducing electromagnetic interferences

- optimizing in-built incoming material selection

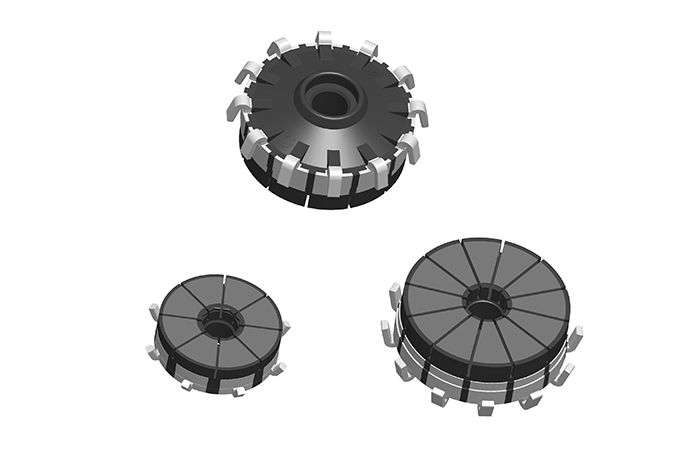

Commutators for auxilary motors

- displacement motors (seat adjustment, electric window lift ...)

- for windshield wipers

- HVAC and EC

- ABS, ESP ...

- other (transmission, e-gas ...)

Commutators for fuel pump motors

- mixed fuel

- unclean fuel

- combined fuel

- bio fuel

- standard fuels

- other

Commutators for fuel starter motors

- start/stop starters

- direct drive

- for trucks

- for construction machinery

- other

Commutators for household appliance motors, industrial motors and power tool motors

- washing machines, vacuum cleaners, small household appliances, fans, other

- wind power plants, forklifts, loading ramps, winches, high pressure cleaners, other

- drilling machines, angle grinders, electric saws, impact hammers, multifunctional tools, other

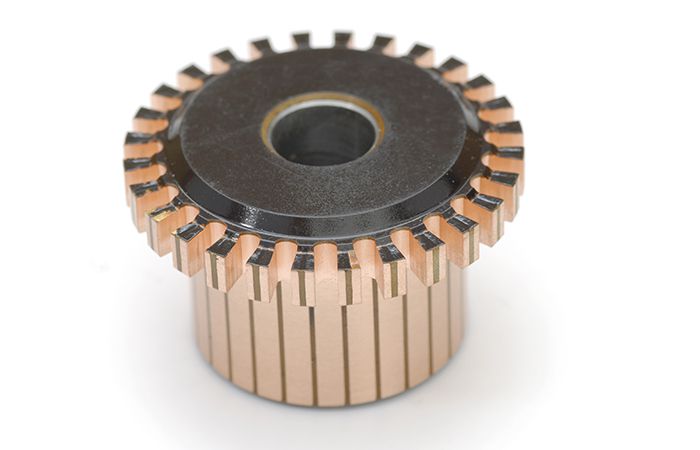

Meeting customer requirements by

- ensuring long life of the commutation system in aggressive fuels

- ensuring the expected life of the high-end household appliances and professional power tools

- ensuring high number of restart cycles in start-stop systems

- reducing electromagnetic interferences

- optimizing in-built incoming material selection

Development partnership

- design optimisation (FEM, FLOW and THERMAL analysis)

- production process optimisation

- optimal material selection

Testing and simulation

- in different fluids, under different temperatures, shocking, humidifying chambers with various temperature and humidity profiles

Several patents from the following fields

- carbon commutators

- reinforced commutators

- commutators made under cold forming

- commutators enabling reduced pollution of the environment with electromagnetic intereferences.

Numerous awards by customers for development partner and supplier of the year.

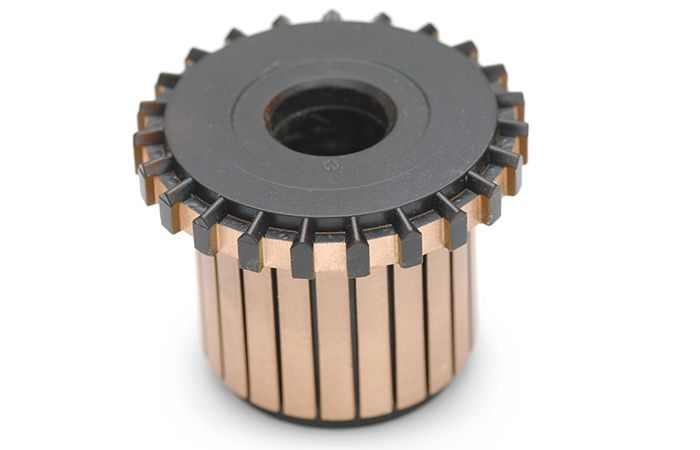

Why work with us

Competences

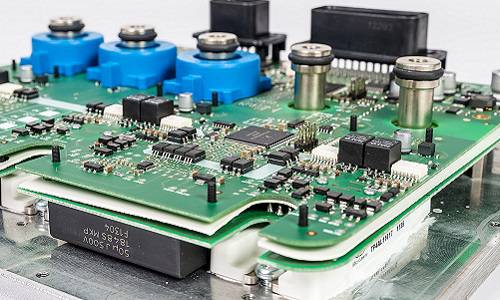

Technological

- application of the state-of-art development tools (ProE, Pro-M,...)

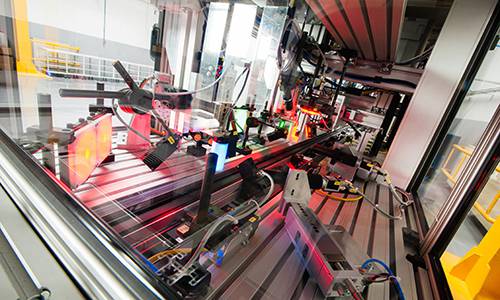

- proper construction and production of tools and machines

- analyses as to potential improvements in commutator mounting

- automation and visual inspection

Organizational

- project management in accordance with customer expectations

- certified management systems (ISO 9001, ISO 14001, TS 16949)

- well organized and flexible logistic processes

Advantages

- complete solution (development, production & support services)

- long tradition and experience in re-forming of copper and injection molding

- established development and quality processes according to quality standards

- in-house manufacture of tools and production equipment for the automation process

- sustained level of quality at all production locations worldwide

- reliable partner ensuring optimal relation between quality and price

Contact us

Together we can find the right solution